Unlocking Your Wheel's Secrets: A Comprehensive Guide to Bolt Pattern Sizing

Ever stared at your car’s wheels, wondering what mysteries lie beneath those shiny metal discs? Well, one crucial secret they hold is their bolt pattern size, a piece of information so vital it could be the difference between a smooth ride and a wobbly, potentially dangerous drive. Knowing your bolt pattern is like knowing your blood type before a transfusion – critical for compatibility.

Think about it. You’re itching to upgrade your car's look with some slick new rims. You browse online, find the perfect set, and click “buy.” But then, disaster strikes. The wheels arrive, and they just won’t fit. Why? You guessed it – the bolt pattern. This seemingly small detail can bring your automotive dreams crashing down. So, how do you avoid this automotive heartbreak? Let’s dive into the fascinating world of wheel bolt patterns.

Understanding how to identify wheel bolt pattern size is fundamental for any car owner, especially those considering aftermarket wheels. The bolt pattern, also known as the lug pattern or PCD (Pitch Circle Diameter), determines how the wheel attaches to the hub. It’s essentially a blueprint, a code that ensures a secure and balanced connection. Getting this right is not just about aesthetics; it’s about safety.

The history of the wheel bolt pattern is intertwined with the evolution of the automobile itself. As cars became more complex, the need for standardized and reliable wheel attachment systems grew. The bolt pattern emerged as a solution, allowing for interchangeable wheels and simplifying the manufacturing process. It’s a small but significant part of automotive history.

Determining the bolt pattern size isn't rocket science, but it requires a little bit of detective work. There are a few different methods, each with its own level of complexity. Knowing the right technique for your specific wheel setup can save you time, frustration, and potentially some serious cash.

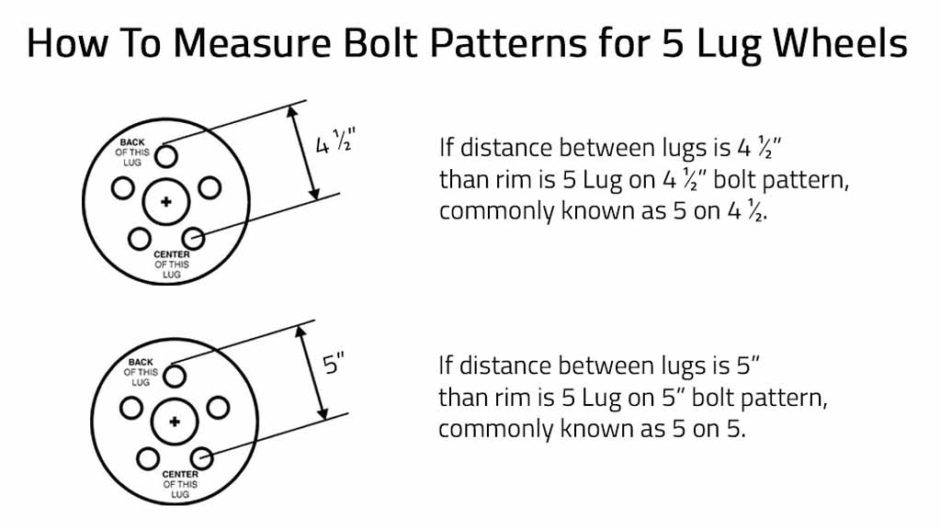

The bolt pattern is expressed as two numbers. The first number indicates the number of lug nuts or bolts, and the second number represents the diameter of the circle formed by the center of those lug holes. For example, a 5x114.3 bolt pattern means there are five lug nuts, and the circle connecting their centers measures 114.3 millimeters in diameter.

One simple method for measuring bolt patterns with an even number of lugs is to measure the distance between the center of one lug hole to the center of the lug hole directly opposite it. For odd-numbered lug patterns, the process is slightly more involved, often requiring measuring from the center of one lug to a point on the opposite rim edge and using some geometry.

Knowing your wheel bolt pattern is beneficial in several ways. Firstly, it ensures a perfect fitment, preventing wobbly wheels and potential damage. Secondly, it allows you to explore aftermarket wheel options without the risk of incompatibility. Lastly, it empowers you with knowledge, turning you from a passive consumer into an informed car owner.

To determine your bolt pattern, you can refer to your car’s owner’s manual, check for stickers inside the glove compartment or on the driver-side doorjamb, or use online resources like wheel-size.com. There are also numerous apps available that help you identify your bolt pattern by taking a picture of your wheel.

Advantages and Disadvantages of Manually Determining Wheel Bolt Pattern

| Advantages | Disadvantages |

|---|---|

| Cost-effective (no tools required) | Can be inaccurate if not measured carefully |

| Can be done anywhere, anytime | Challenging with odd-numbered lug patterns |

| Empowering and educational | Time-consuming compared to using online resources |

Best Practices:

1. Double-Check: Always verify your findings using multiple resources.

2. Cleanliness: Ensure the wheel hub is clean for accurate measurements.

3. Proper Tools: Use a precise ruler or caliper for measurement.

4. Consult Experts: If uncertain, seek professional help from a tire shop.

5. Online Resources: Utilize reputable websites and databases for cross-referencing.

Challenges and Solutions:

1. Rusted or Damaged Lugs: Use a wire brush to clean before measuring.

2. Odd-Numbered Lug Patterns: Use the diagonal measurement method or consult a professional.

3. Inconsistent Measurements: Double-check and ensure proper tool usage.

FAQs:

1. What does PCD stand for? Pitch Circle Diameter.

2. Why is knowing my bolt pattern important? Ensures proper wheel fitment and safety.

3. Where can I find my car’s bolt pattern information? Owner’s manual, doorjamb sticker, online resources.

Tips and Tricks: Take clear photos of your wheels for easy reference. Keep a record of your car’s bolt pattern along with other important vehicle information.

In conclusion, understanding how to ascertain your wheel bolt pattern size is a fundamental aspect of car ownership. It empowers you to make informed decisions regarding wheel upgrades, ensuring safety, compatibility, and a smooth driving experience. By understanding the different methods, best practices, and potential challenges, you can navigate the world of wheel bolt patterns with confidence. Don't let this seemingly small detail derail your automotive aspirations. Take the time to learn your bolt pattern, and enjoy the ride knowing you’ve got the right fit. It's a small investment of time that can save you a lot of headaches down the road. So, go ahead, unlock the secrets of your wheels!

Ancient ink the allure of egyptian leg sleeve tattoos

Hiv testing validity for marriage in kedah

Transform your living room wall decor ideas inspiration