The Heart of a Jumbo Jet: Exploring the Boeing 747's Engines

Ever looked up at a Boeing 747 soaring through the sky and wondered what gives this massive aircraft its lift? The answer, of course, lies in its powerful engines. These complex machines are a marvel of engineering, providing the thrust necessary to carry hundreds of passengers and tons of cargo across vast distances.

The Boeing 747, affectionately nicknamed the "Queen of the Skies," has been powered by a variety of engine types throughout its history. Understanding which engine a particular 747 uses is key to grasping its performance capabilities, fuel efficiency, and overall impact on aviation.

From the early days of high-bypass turbofan engines to the more modern and efficient iterations, the 747's power plants have continuously evolved. This evolution reflects the ongoing quest for quieter, more fuel-efficient, and environmentally friendly air travel. This journey through the different engine types reveals the advancements in aerospace technology and the constant push for improvement.

So, what engine does the Boeing 747 use? The answer isn't straightforward, as it depends on the specific model of the 747. Earlier models, like the 747-100, -200, and -300, were often equipped with Pratt & Whitney JT9D or General Electric CF6 engines. These early high-bypass turbofans were a significant step forward in jet engine technology, offering improved fuel efficiency and noise reduction compared to their predecessors.

Later versions, like the 747-400, the most widely produced variant, generally employed more advanced engines, such as the Pratt & Whitney PW4000, General Electric CF6-80C2, or Rolls-Royce RB211-524G. These engines offered even better performance, reliability, and fuel efficiency, contributing to the 747-400's long reign as a dominant force in long-haul air travel.

The development of the 747's engines has been driven by several factors. Early on, the focus was on producing enough thrust to get this jumbo jet airborne. Later, noise reduction became a significant concern, leading to the development of quieter engines with larger bypass ratios. More recently, fuel efficiency and reducing environmental impact have been primary drivers of engine development.

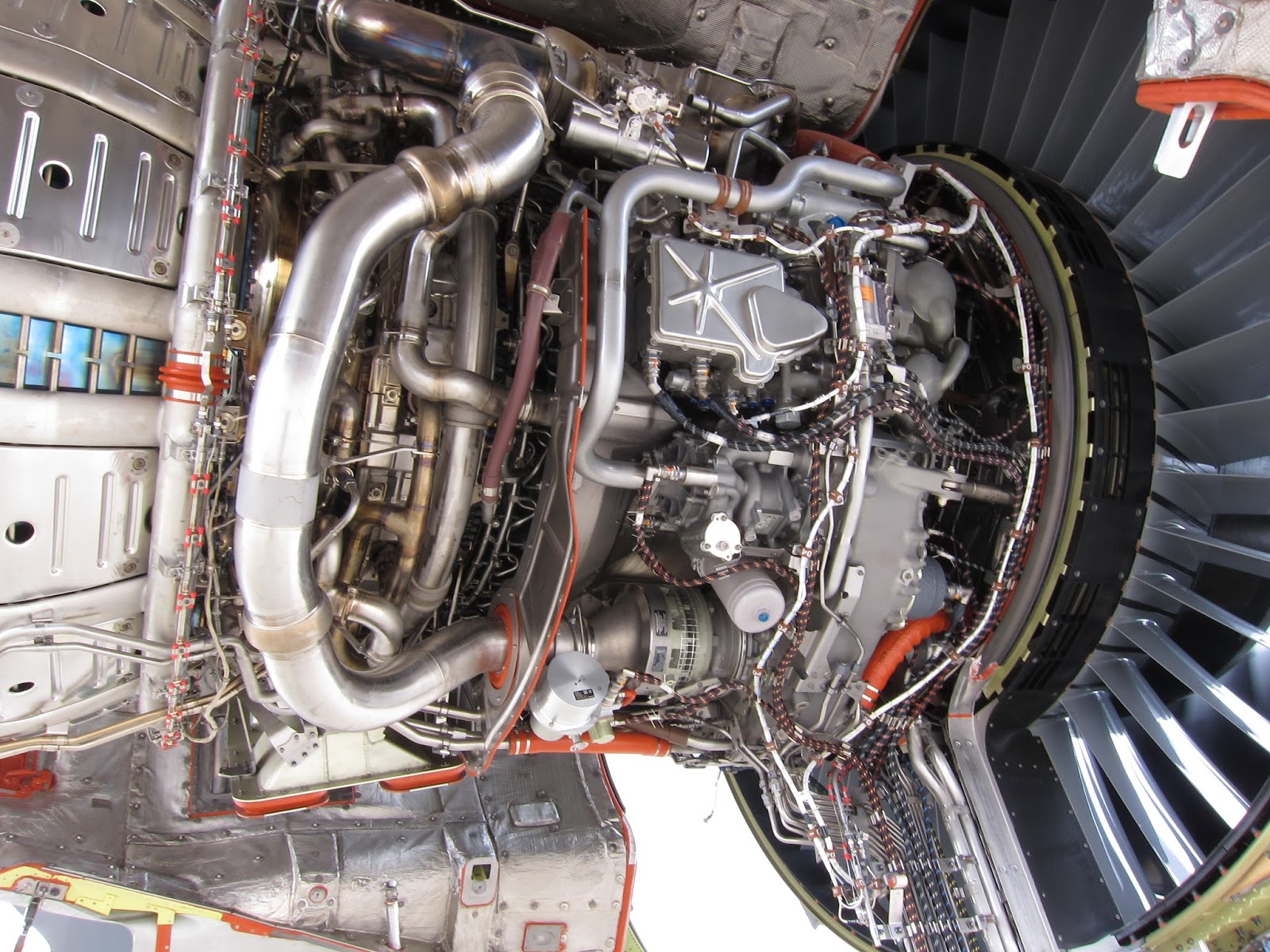

A high-bypass turbofan engine, the typical type used on a 747, works by taking in a large volume of air and splitting it into two streams. One stream passes through the engine core, where it is compressed, mixed with fuel, and ignited. The other stream bypasses the core and mixes with the exhaust gases, increasing thrust and reducing noise.

One of the key benefits of the modern engines used on the 747-400 and later models is their increased fuel efficiency. This efficiency translates into lower operating costs for airlines and reduced emissions. Another benefit is reduced noise, making the aircraft less disruptive to communities near airports.

One of the challenges associated with these large engines is maintenance. These are incredibly complex pieces of machinery, requiring regular inspections and overhauls to ensure they operate safely and efficiently.

Advantages and Disadvantages of 747 Engine Types

| Engine Type | Advantages | Disadvantages |

|---|---|---|

| Pratt & Whitney JT9D | Proven Reliability | Higher Fuel Consumption compared to later models |

| General Electric CF6 | Widely Used, Good Performance | Older Technology |

| Pratt & Whitney PW4000 | High Thrust, Good Fuel Efficiency | More Complex Maintenance |

Frequently Asked Questions:

1. What is a high-bypass turbofan engine? (Answered above)

2. How often do 747 engines need maintenance? Maintenance schedules vary depending on the engine type and operating conditions.

3. How much thrust does a 747 engine produce? This varies depending on the specific engine model.

4. Are all 747 engines the same? No, different 747 models use different engines.

5. What is the most common engine used on the 747? The Pratt & Whitney PW4000 and General Electric CF6-80C2 are common on the 747-400.

6. How do 747 engines contribute to noise reduction? Through the use of high-bypass technology.

7. How does engine technology impact the 747's fuel efficiency? More modern engines are designed for greater fuel efficiency.

8. What is the future of 747 engines? As the 747 is being phased out, focus shifts to engines for newer aircraft.

In conclusion, the engines of the Boeing 747 are integral to its legacy as a groundbreaking aircraft. From the early JT9D engines to the more modern PW4000 and CF6 series, these powerhouses have enabled the Queen of the Skies to connect the world for decades. Understanding the engines used on different 747 models provides valuable insight into the evolution of aerospace technology, the constant drive for improved performance and efficiency, and the ongoing quest for sustainable air travel. The continued development of engine technology will shape the future of aviation, pushing the boundaries of what is possible and connecting the world in even more efficient and environmentally conscious ways. While the 747's reign may be coming to a close, its impact on aviation and the advancements in engine technology it spurred will continue to inspire future generations of engineers and aviators.

Unleash your inner morticia a deep dive into dark coloring books for adults

Conquer your semester mastering the penn state class schedule

Decoding the jon boat drain tube your tiny vessels unsung hero