Illuminating the Path: A Comprehensive Guide to Boat Trailer Rewiring

There's a certain magic to the open water, a siren song that calls to the adventurous spirit. But before you can answer that call, you must ensure your vessel's safe passage to its watery domain. This journey begins not on the waves, but on the road, with a trailer whose electrical integrity is paramount. A properly wired trailer isn't merely a legal requirement; it's a vital link between your terrestrial journey and the aquatic adventure that awaits. This exploration delves into the art and science of boat trailer wiring, offering a comprehensive guide to illuminating your path to nautical bliss.

Imagine the frustration of a launch ramp delay caused by faulty trailer lights. Worse yet, picture the potential dangers of navigating roadways at night with an unilluminated trailer. These scenarios underscore the critical importance of understanding your trailer's electrical system. This guide provides a foundational understanding of boat trailer wiring, empowering you to maintain, troubleshoot, and even completely revamp your trailer's electrical connections.

The history of boat trailers is intertwined with the evolution of boating itself. As boats became larger and more complex, the need for reliable transport grew. Early trailers were simple affairs, often little more than modified farm wagons. The electrical systems, if any, were rudimentary. But with advancements in automotive technology, trailer wiring evolved, incorporating standardized connectors and lighting systems for increased safety and reliability. Today, understanding the nuances of this system is essential for any boat owner.

A key aspect of boat trailer rewiring lies in grasping the common issues that plague these systems. Corrosion, due to constant exposure to moisture and saltwater, is a primary culprit. Frayed wires, damaged connectors, and blown fuses are also frequent offenders. Recognizing these potential problems allows for proactive maintenance and prevents frustrating breakdowns.

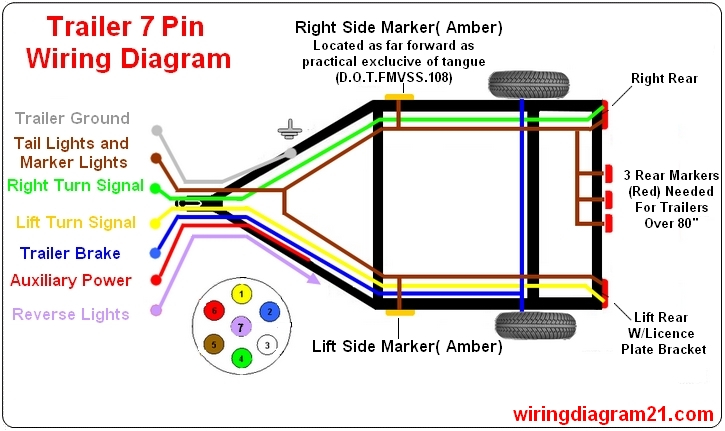

Before embarking on a rewiring project, familiarizing yourself with the essential components is crucial. The wiring harness, the backbone of the system, consists of color-coded wires transmitting power to the lights. The connectors, typically a flat-four or seven-way plug, establish the connection between the tow vehicle and the trailer. Understanding the function of each wire and connector is fundamental to successful rewiring.

Benefit 1: Enhanced Safety. A properly functioning trailer lighting system significantly increases visibility on the road, reducing the risk of accidents.

Benefit 2: Legal Compliance. Adhering to wiring regulations ensures you meet legal requirements, avoiding potential fines and penalties.

Benefit 3: Peace of Mind. Knowing your trailer's electrical system is reliable provides peace of mind, allowing you to focus on enjoying your time on the water.

Creating an Action Plan: Start by assessing the current wiring. Identify any damaged or corroded components. Gather the necessary tools and materials, including marine-grade wiring, connectors, and heat shrink tubing.

Checklist: Marine-grade wiring, waterproof connectors, heat shrink tubing, wire strippers/crimpers, electrical tape, test light.

Step-by-step guide: 1. Disconnect the trailer from the tow vehicle. 2. Inspect the wiring harness for damage. 3. Replace any corroded or damaged wires. 4. Connect the new wiring to the lights and connectors. 5. Test the lights to ensure they are functioning correctly.

Advantages and Disadvantages of Rewiring a Boat Trailer

| Advantages | Disadvantages |

|---|---|

| Improved Safety | Time Commitment |

| Cost Savings (DIY) | Potential for Errors |

Best Practices: 1. Use marine-grade wiring. 2. Waterproof all connections. 3. Use heat shrink tubing to protect connections. 4. Ground the system properly. 5. Test the system thoroughly after rewiring.

Examples: Replace corroded connectors, repair damaged wiring, install new lights, upgrade to LED lights, install a brake controller.

Challenges and Solutions: Corrosion - use marine-grade wiring and waterproof connectors; Frayed wires - replace damaged sections; Blown fuses - identify and rectify the underlying cause; Faulty connectors - replace with new, waterproof connectors; Dim lights - check for poor connections or inadequate grounding.

FAQ: What type of wire should I use? How do I test the lights? What are the common wiring problems? How do I connect the wires to the connectors? What gauge wire should I use? How do I ground the system? What is a wiring diagram? Where can I find wiring diagrams for my trailer?

Tips and Tricks: Use dielectric grease on connections. Secure the wiring harness to the trailer frame. Use a test light to identify wiring issues. Consult a wiring diagram for your specific trailer model.

The ability to confidently and competently rewire your boat trailer transforms a potentially daunting task into an empowering act of self-reliance. By understanding the intricacies of the electrical system, you ensure not only the safe transport of your vessel but also the longevity and reliability of your trailer. From understanding the historical context of trailer wiring to mastering the practical steps involved, this guide provides the knowledge and resources needed to illuminate your journey to the water. This knowledge not only safeguards your investment and enhances your boating experience but fosters a deeper appreciation for the interconnectedness of craft and adventure. Invest the time, embrace the process, and enjoy the rewards of a well-maintained and safely illuminated path to your aquatic passions.

Decoding the enigma of carpet odors a deep dive into smell removal

Josh johnson comedian birthday celebration

Keeping cool on the road rv ac repair and parts