Decoding the NC Float Switch Symbol: Your Guide to Liquid Level Control

Ever wondered how your sump pump knows when to kick on or your coffee maker knows when to stop brewing? The answer often lies in a small but mighty component: the NC float switch. And understanding the NC float switch symbol is key to unlocking its secrets. So, grab a cup of coffee (hopefully not brewed by a malfunctioning float switch!), and let's dive in.

The "NC" in NC float switch stands for "normally closed." This means that in its default state, without any liquid acting on it, the switch's electrical circuit is closed, allowing current to flow. When the liquid level rises and lifts the float, the switch opens, breaking the circuit and stopping the current. This seemingly simple action is the foundation of a wide range of liquid level control systems, from the mundane to the mission-critical.

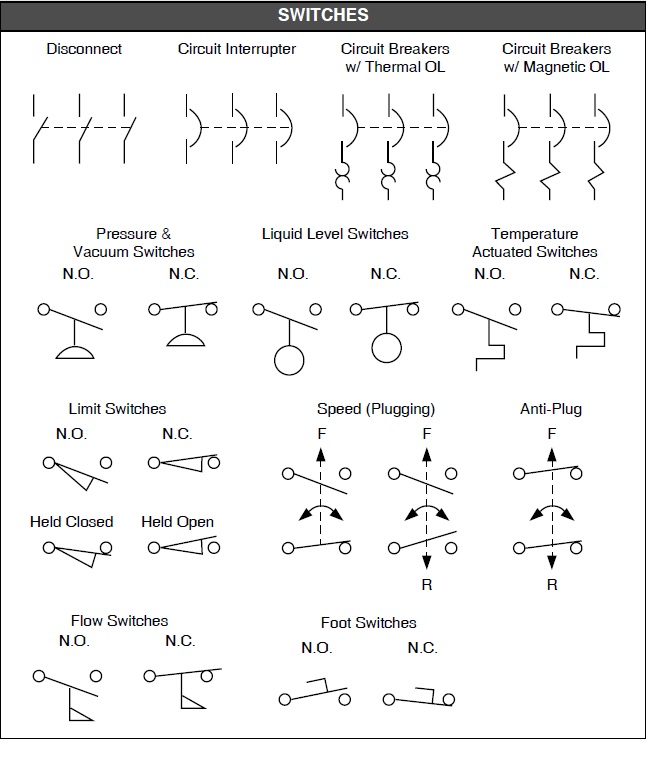

The NC float switch symbol, typically depicted as a switch with a line connecting its terminals and an arrow indicating its normally closed position, is crucial for anyone working with electrical diagrams or control systems. Understanding this symbol allows you to quickly identify the type of float switch used and its function within the broader system. Misinterpreting this symbol could lead to incorrect wiring, malfunctioning equipment, or even safety hazards.

While the exact origin of the float switch is difficult to pinpoint, its basic principle—using buoyancy to control a switch—has been employed for centuries. Early versions likely involved simple levers and floats made from readily available materials like wood or cork. The modern, electrically operated float switch, however, is a more recent development, emerging with the rise of automated control systems in the 20th century. Its importance in various industries, including manufacturing, wastewater management, and even home appliances, cannot be overstated.

A major issue related to NC float switches is their susceptibility to malfunction due to debris, corrosion, or mechanical wear. Regular maintenance and proper installation are crucial for ensuring reliable operation. Another challenge is selecting the correct type of float switch for a specific application, considering factors such as liquid density, temperature, and pressure.

A simple example of an NC float switch in action is in a sump pump. When water in the sump pit rises to a certain level, the float rises, opening the NC switch and turning off the pump. As the water level drops, the float lowers, closing the switch and activating the pump again.

One benefit of an NC float switch is its fail-safe operation in certain applications. For instance, in an overflow protection system, the normally closed configuration ensures that the system will trigger an alarm or shut off a process if the switch fails. Another advantage is its simplicity and relatively low cost compared to more complex level sensing technologies.

If your sump pump uses an NC float switch and isn't working correctly, a simple troubleshooting step is to check the switch for debris or damage. Ensure the float moves freely and that the switch opens and closes correctly when manually actuated.

Advantages and Disadvantages of NC Float Switches

| Advantages | Disadvantages |

|---|---|

| Simple and cost-effective | Susceptible to debris and wear |

| Fail-safe operation in some applications | Limited accuracy compared to other level sensors |

| Easy to install and maintain | Can be affected by turbulent liquids |

One best practice for implementing NC float switches is to ensure proper wiring, following the manufacturer's instructions and using appropriate wire gauge and connectors.

A real-world example is the use of NC float switches in industrial tanks to control the level of liquids like chemicals or wastewater. The switch triggers alarms or activates pumps to maintain the desired liquid level.

One challenge with NC float switches is that they can be affected by turbulent liquids, leading to inaccurate readings. A solution is to use a stilling well or baffle to dampen the turbulence around the float.

FAQ: What does NC stand for in a float switch? NC stands for Normally Closed.

One tip for using NC float switches is to regularly inspect them for signs of wear and tear, especially in harsh environments.

In conclusion, the NC float switch, represented by its distinct symbol, plays a vital role in various liquid level control applications. From managing water levels in sump pumps to controlling industrial processes, these simple yet effective devices offer a reliable and cost-effective solution. Understanding the NC float switch symbol, its operation, and best practices for implementation is essential for anyone working with these systems. By properly selecting, installing, and maintaining NC float switches, you can ensure the efficient and safe operation of your liquid level control systems, preventing costly downtime and potential hazards. Take the time to familiarize yourself with the nuances of these essential components, and you'll be well-equipped to harness their power for a wide range of applications. The correct understanding and application of NC float switches can significantly improve efficiency and safety in various systems, justifying the time and effort invested in learning about them.

The anticipated reappearance of the sss class ranker 80

The symphony of a 3 month old que hace un bebe de 3 meses

Gachatubers secret weapon unveiling the editing apps they use