Conquer Bilge Pump Wiring: Keep Your Boat Afloat

A sinking feeling. That's what you get when your boat starts taking on water and your bilge pump isn't working. Don't let a faulty bilge pump ruin your day on the water. Understanding your boat's bilge pump wiring diagram is crucial for maintaining a safe and seaworthy vessel. This guide will walk you through everything you need to know, from interpreting the schematic to troubleshooting common issues.

Bilge pumps are the heart of your boat's drainage system, responsible for removing unwanted water that accumulates in the bilge. A properly functioning bilge pump can prevent serious problems, from a swamped boat to potential sinking. The key to a reliable bilge pump setup lies in a correctly wired system. Knowing how to read and implement a bilge pump wiring schematic is essential for any boat owner.

The evolution of bilge pump systems has mirrored advancements in boat design and technology. Early systems were often manual, requiring physical effort to operate. With the advent of electricity, automatic bilge pumps became the standard, providing a critical safety feature. Modern bilge pump wiring diagrams incorporate features like float switches, alarms, and multiple pumps for added redundancy. These diagrams have become increasingly complex to accommodate these features, highlighting the importance of understanding their intricacies.

One of the most common problems boat owners face is a malfunctioning bilge pump. Often, the culprit isn't a faulty pump, but rather incorrect wiring. A poorly executed bilge pump electrical diagram can lead to a range of issues, from a pump that won't activate to a constantly running pump that drains your battery. Troubleshooting these problems requires a solid understanding of the wiring diagram and the ability to identify potential connection errors.

A bilge pump wiring schematic is essentially a roadmap of your bilge pump system. It visually represents the connections between the pump, the power source, the float switch, and any other components. Understanding this roadmap is paramount to installing, maintaining, and troubleshooting your bilge pump system. This guide will empower you with the knowledge to keep your boat afloat and worry-free.

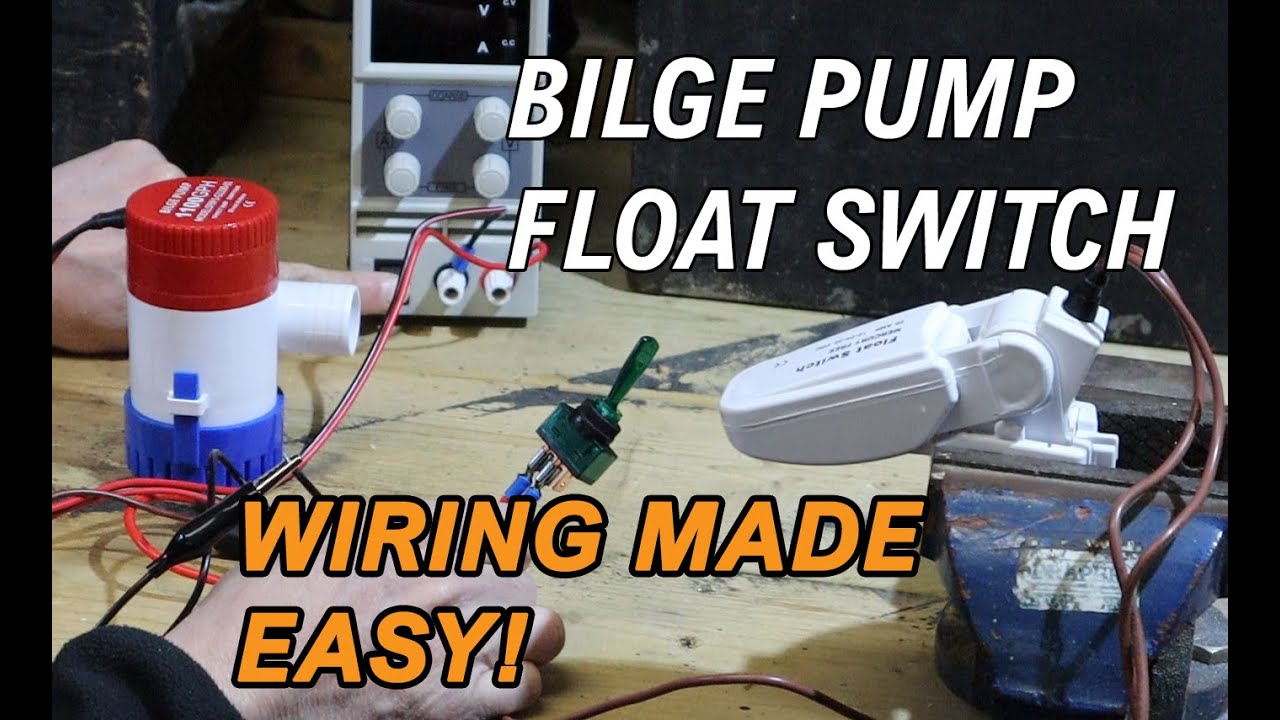

A bilge pump wiring diagram typically includes the battery, fuse, switch, float switch, and the pump itself. The float switch automatically activates the pump when water reaches a certain level. The fuse protects the circuit from overloads. Understanding the function of each component within the schematic is crucial for proper installation and maintenance.

Three key benefits of using a proper bilge pump wiring diagram are: Safety - A correctly wired pump ensures automatic operation, preventing flooding and potential sinking. Reliability - Proper wiring minimizes malfunctions and ensures the pump operates when needed. Efficiency - Correct wiring prevents battery drain from a constantly running pump or a short circuit.

Action Plan: 1. Obtain the correct wiring diagram for your specific bilge pump model. 2. Gather the necessary tools and materials, including marine-grade wiring, connectors, and fuses. 3. Carefully follow the diagram, ensuring all connections are secure and waterproof. 4. Test the system thoroughly to verify proper operation.

Advantages and Disadvantages of using a Wiring Diagram

| Advantages | Disadvantages |

|---|---|

| Ensures correct installation | Can be complex for beginners |

| Facilitates troubleshooting | Requires understanding of electrical systems |

| Promotes safety and reliability | Incorrect interpretation can lead to malfunctions |

Best Practices: 1. Use marine-grade wiring and connectors to prevent corrosion. 2. Install an inline fuse to protect the circuit. 3. Ensure all connections are waterproof and secure. 4. Regularly inspect and test the system. 5. Consult a professional if you are unsure about any aspect of the installation.

FAQ: 1. What type of wire should I use? Marine-grade wire is essential. 2. Where should the fuse be located? As close to the battery as possible. 3. How often should I test the pump? At least once a month. 4. What if my pump won't turn off? Check the float switch. 5. Can I install multiple pumps? Yes, using a proper wiring diagram. 6. What if my diagram is missing? Consult the pump manufacturer. 7. How do I test the float switch? Manually lift it to simulate rising water. 8. Do I need a special switch for the bilge pump? A waterproof switch is recommended.

Tips & Tricks: Label all wires clearly. Use heat shrink tubing to protect connections. Double-check all connections before testing. Keep a spare fuse onboard.

A properly functioning bilge pump is essential for boat safety. Understanding and implementing a correct bilge pump wiring plan is paramount for protecting your vessel and ensuring a worry-free boating experience. By following the guidelines and best practices outlined in this guide, you can confidently install, maintain, and troubleshoot your bilge pump system. Taking the time to understand your boat's bilge pump circuit ensures your safety on the water and prevents potential disasters. Remember to consult with a qualified marine electrician if you have any doubts or encounter complex issues. Don’t wait for a flooded bilge to realize the importance of a well-maintained bilge pump system. Invest the time now to familiarize yourself with your bilge pump wiring diagram and keep your boat afloat for years to come. Act now, your boat will thank you later.

Nassau county jail east meadow understanding the complexities

The allure and controversy of evil tribal tattoo ideas

Conquering the lanes a summit peak bowling ball deep dive